Çin Profesyonel ANSI/DIN Dövme Karbon/Paslanmaz Çelik Wn/Kör/So/Düz Flanşlar için stratejik düşünceye, tüm segmentlerde sürekli modernizasyona, teknolojik gelişmelere ve elbette başarımıza doğrudan katkıda bulunan çalışanlarımıza güveniyoruz. Kuruluşumuzun prensibi, yüksek kaliteli ürünler, uzman hizmet ve dürüst iletişim sunmaktır. Uzun vadeli bir iş ilişkisi kurmak için tüm yakın dostlarımızı deneme amaçlı satın alma işlemi yapmaya davet ediyoruz.

Stratejik düşünceye, tüm alanlarda sürekli modernleşmeye, teknolojik gelişmelere ve elbette başarımıza doğrudan katkıda bulunan çalışanlarımıza güveniyoruz.Çin Wn Flanşı, Kaynaklı Boyun FlanşlarıÜrünlerimiz ağırlıklı olarak Güneydoğu Asya, Avrupa ve Amerika'ya ihraç edilmekte olup, ülkemizin her yerine de satış yapmaktayız. Mükemmel kalite, uygun fiyat ve en iyi hizmet anlayışımız sayesinde, yurtdışındaki müşterilerimizden olumlu geri bildirimler aldık. Daha fazla olanak ve avantaj için bize katılmanızı bekliyoruz. Dünyanın her yerinden müşterilerimizi, iş ortaklarımızı ve dostlarımızı bizimle iletişime geçmeye ve karşılıklı fayda için iş birliği yapmaya davet ediyoruz.

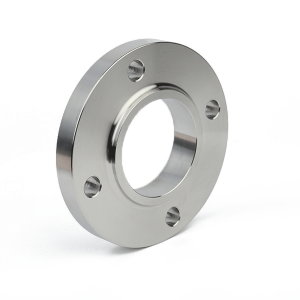

Özellikler

| Ürün Adı | Kör flanş |

| Boyut | 1/2"-250" |

| Basınç | 150#-2500#,PN0.6-PN400,5K-40K,API 2000-15000 |

| Standart | ANSI B16.5,EN1092-1, SABA1123, JIS B2220, DIN, GOST,UNI,AS2129, API 6A, vb. |

| Duvar kalınlığı | SCH5S, SCH10S, SCH10, SCH40S,STD, XS, XXS, SCH20,SCH30,SCH40, SCH60, SCH80, SCH160, XXS vb. |

| Malzeme | Paslanmaz çelik:A182F304/304L, A182 F316/316L, A182F321, A182F310S, A182F347H, A182F316Ti, 317/317L, 904L, 1.4301, 1.4307, 1.4401, 1.4571, 1.4541, 254Mo ve benzeri. |

| Karbon çeliği:A105, A350LF2, S235Jr, S275Jr, St37, St45.8, A42CP, A48CP, E24, A515 Gr60, A515 Gr 70 vb. | |

| Dubleks paslanmaz çelik: UNS31803, SAF2205, UNS32205, UNS31500, UNS32750, UNS32760, 1.4462, 1.4410, 1.4501 vb. | |

| Boru hattı çeliği:A694 F42, A694F52, A694 F60, A694 F65, A694 F70, A694 F80 vb. | |

| Nikel alaşımı:inconel600, inconel625, inconel690, incoloy800, incoloy 825, incoloy 800H, C22, C-276, Monel400, Alloy20 vb. | |

| Krom-Molibden alaşımı:A182F11, A182F5, A182F22, A182F91, A182F9, 16mo3, 15Crmo, vb. | |

| Başvuru | Petrokimya endüstrisi; havacılık ve uzay endüstrisi; ilaç endüstrisi; gaz egzozu; enerji santrali; gemi inşaatı; su arıtma, vb. |

| Avantajlar | Hazır stok, daha hızlı teslimat süresi; tüm boyutlarda mevcut, özelleştirilebilir; yüksek kalite |

Ürün detayları gösterimi

1. Yüz

Yükseltilmiş yüzey (RF), tam yüzey (FF), halka eklem (RTJ), oluklu, dilli veya özelleştirilmiş olabilir.

2. Yüzeyi kapatın.

Pürüzsüz yüz, göz altı çizgileri, tırtıklı bitiş

3. CNC hassas işleme

Yüzey işleme: Flanşın yüzeyindeki işleme, Aritmetik Ortalama Pürüzlülük Yüksekliği (AARH) olarak ölçülür. İşleme, kullanılan standarda göre belirlenir. Örneğin, ANSI B16.5, 125AARH-500AARH (3,2Ra ila 12,5Ra) aralığında yüzey işlemeleri belirtir. Talep üzerine diğer işlemeler de mevcuttur, örneğin 1,6 Ra maksimum, 1,6/3,2 Ra, 3,2/6,3 Ra veya 6,3/12,5 Ra. 3,2/6,3Ra aralığı en yaygın olanıdır.

İşaretleme ve Paketleme

• Her katmanda yüzeyi korumak için plastik film kullanılmıştır.

• Tüm paslanmaz çelik ürünler kontrplak kasa ile paketlenir. Daha büyük boyutlu karbon flanşlar kontrplak palet ile paketlenir. Veya isteğe özel ambalajlama yapılabilir.

• İstek üzerine sevkiyat işareti yapılabilir.

• Ürünler üzerindeki işaretler oyma veya baskı yöntemiyle yapılabilir. OEM siparişleri kabul edilir.

Denetleme

• UT testi

• PT testi

• MT testi

• Boyut testi

Teslimattan önce, kalite kontrol ekibimiz tahribatsız muayene (NDT) ve boyut kontrolü işlemlerini gerçekleştirecektir. Ayrıca üçüncü taraf denetimi (TPI) de kabul ediyoruz.

Üretim süreci

| 1. Orijinal ham madde seçin. | 2. Ham maddeyi kesin. | 3. Ön ısıtma |

| 4. Dövme | 5. Isıl işlem | 6. Kaba İşleme |

| 7. Sondaj | 8. Hassas işleme | 9. İşaretleme |

| 10. Muayene | 11. Paketleme | 12. Teslimat |

İşbirliği örneği

Bu sipariş Malezya'daki stokçu içindir. Malları teslim aldıktan sonra müşteri bize beş yıldızlı olumlu yorumlar verdi. Onun tavsiyeleri doğrultusunda boyama işimizi geliştirdik.

Çin Profesyonel ANSI/DIN Dövme Karbon/Paslanmaz Çelik Wn/Kör/So/Düz Flanşlar için stratejik düşünceye, tüm segmentlerde sürekli modernizasyona, teknolojik gelişmelere ve elbette başarımıza doğrudan katkıda bulunan çalışanlarımıza güveniyoruz. Kuruluşumuzun prensibi, yüksek kaliteli ürünler, uzman hizmet ve dürüst iletişim sunmaktır. Uzun vadeli bir iş ilişkisi kurmak için tüm yakın dostlarımızı deneme amaçlı satın alma işlemi yapmaya davet ediyoruz.

Çinli Profesyonel Çin Wn Flanşları, Kaynaklı Boyunlu Flanşlar. Ürünlerimiz ağırlıklı olarak Güneydoğu Asya, Avrupa ve Amerika'ya ihraç edilmekte olup, ülkemizin her yerine de satılmaktadır. Mükemmel kalite, uygun fiyat ve en iyi hizmet anlayışımız sayesinde, yurtdışındaki müşterilerimizden olumlu geri bildirimler aldık. Daha fazla olanak ve avantaj için bize katılmaya davetlisiniz. Dünyanın her yerinden müşterileri, iş ortaklarını ve dostlarımızı bizimle iletişime geçmeye ve karşılıklı fayda için iş birliği aramaya davet ediyoruz.

Ürün detayları gösterimi

1. Yüz

Yükseltilmiş yüzey (RF), tam yüzey (FF), halka eklem (RTJ), oluklu, dilli veya özelleştirilmiş olabilir.

2. Yüzeyi kapatın.

Pürüzsüz yüz, göz altı çizgileri, tırtıklı bitiş

3. CNC hassas işleme

Yüzey işleme: Flanşın yüzeyindeki işleme, Aritmetik Ortalama Pürüzlülük Yüksekliği (AARH) olarak ölçülür. İşleme, kullanılan standarda göre belirlenir. Örneğin, ANSI B16.5, 125AARH-500AARH (3,2Ra ila 12,5Ra) aralığında yüzey işlemeleri belirtir. Talep üzerine diğer işlemeler de mevcuttur, örneğin 1,6 Ra maksimum, 1,6/3,2 Ra, 3,2/6,3 Ra veya 6,3/12,5 Ra. 3,2/6,3Ra aralığı en yaygın olanıdır.

İşaretleme ve Paketleme

• Her katmanda yüzeyi korumak için plastik film kullanılmıştır.

• Tüm paslanmaz çelik ürünler kontrplak kasa ile paketlenir. Daha büyük boyutlu karbon flanşlar kontrplak palet ile paketlenir. Veya isteğe özel ambalajlama yapılabilir.

• İstek üzerine sevkiyat işareti yapılabilir.

• Ürünler üzerindeki işaretler oyma veya baskı yöntemiyle yapılabilir. OEM siparişleri kabul edilir.

Denetleme

• UT testi

• PT testi

• MT testi

• Boyut testi

Teslimattan önce, kalite kontrol ekibimiz tahribatsız muayene (NDT) ve boyut kontrolü işlemlerini gerçekleştirecektir. Ayrıca üçüncü taraf denetimi (TPI) de kabul ediyoruz.

Üretim süreci

| 1. Orijinal ham madde seçin. | 2. Ham maddeyi kesin. | 3. Ön ısıtma |

| 4. Dövme | 5. Isıl işlem | 6. Kaba İşleme |

| 7. Sondaj | 8. Hassas işleme | 9. İşaretleme |

| 10. Muayene | 11. Paketleme | 12. Teslimat |

İşbirliği örneği

Bu sipariş Malezya'daki stokçu içindir. Malları teslim aldıktan sonra müşteri bize beş yıldızlı olumlu yorumlar verdi. Onun tavsiyeleri doğrultusunda boyama işimizi geliştirdik.

Boru bağlantı parçaları, boru sisteminde bağlantı, yönlendirme, kanal değiştirme, boyut değiştirme, sızdırmazlık veya sıvı akışını kontrol etme gibi amaçlarla kullanılan hayati öneme sahip bileşenlerdir. İnşaat, sanayi, enerji ve belediye hizmetleri gibi alanlarda yaygın olarak kullanılırlar.

Başlıca İşlevler:Boruları birbirine bağlama, akış yönünü değiştirme, akışları bölme ve birleştirme, boru çaplarını ayarlama, boruları sızdırmaz hale getirme, kontrol ve düzenleme gibi işlevleri yerine getirebilir.

Uygulama Kapsamı:

- Bina su temini ve drenajı:PVC dirsekler ve PPR üçgen bağlantı parçaları su boru şebekelerinde kullanılır.

- Endüstriyel boru hatları:Kimyasal maddelerin taşınmasında paslanmaz çelik flanşlar ve alaşımlı çelik dirsekler kullanılır.

- Enerji taşımacılığı:Yüksek basınçlı çelik boru bağlantı parçaları petrol ve doğalgaz boru hatlarında kullanılır.

- Isıtma, Havalandırma ve Klima (HVAC):Bakır boru bağlantı parçaları soğutucu boru hatlarını birleştirmek için kullanılır ve esnek bağlantı elemanları titreşimi azaltmak için kullanılır.

- Tarımsal sulama:Hızlı bağlantı elemanları, fıskiyeli sulama sistemlerinin montajını ve demontajını kolaylaştırır.